..............................................................................................................................................................

Portland Cement

By: Haseeb Jamal

Manufacturing

of Portland Cement

Definition

of OPC

Cement

can be defined as the bonding material having cohesive & adhesive

properties which makes it capable to unite the different construction materials

and form the compacted assembly.

Ordinary/Normal

Portland cement is one of the most widely used type of Portland Cement.

The

name Portland cement was given by Joseph Aspdin in 1824 due to its similarity

in colour and its quality when it hardens like Portland stone.

Portland

stone is white grey limestone in island of Portland, Dorset.

Production

& Manufacturing:

Today,

Ordinary Portland cement is the most widely used building material in the world

with about 1.56 billion tones produced each year.

Annual

global production of Portland cement concrete is around 3.8 million cubic

meters per year.

In Pakistan; cement production will go beyond

45 million tons per year in the next two years

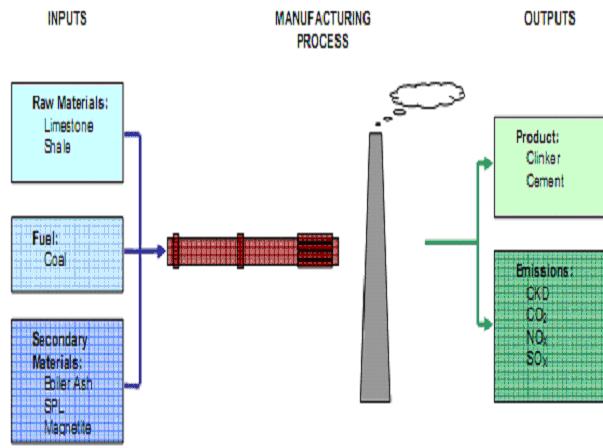

Manufacturing

Raw

Materials

Calcareous

(material having content of lime)

Argillaceous

(material having contents of silica & alumina)

Gypsum

Process

Cement

is usually manufactured by two processes:

Wet

process

Dry

process

These

two processes differ in operation but fundamentals of both these processes are

same.

In

Pakistan, most of the factories use Wet Process for the production of cement.

There are five stages in manufacturing of cement by wet process:

Crushing

and grinding of raw material

Mixing

the material in proportion

Heating

the prepared mixture in rotary kiln

Grinding

the heated product known as clinker

Mixing

and grinding of cement clinker with gypsum

Crushing

and Grinding:

In

this phase, soft raw materials are first crushed into suitable size. This is

done usually in cylindrical ball or tube mills containing the charge of steel

balls

Mixing

the Material:

In

this part, the powdered limestone is mixed with the clay paste in proper

proportion (75%=lime stone; clay=25%)

The

mixture is then grounded and made homogeneous by mean of compressed gas. The

resulting material is known as slurry having 35-40% water.

Heating

the slurry in rotary kiln:

Slurry

is then introduced in rotary kiln with help of conveyor. The rotary kiln

consists of large cylinders 8 to 15 feet in diameter & height of 300-500

feet. It is made with steel & is usually lined inside with firebricks.

Rotary

Kiln

Kiln

rotates at the rate of 1-2 revolution per minute. In rotary kiln, slurry is

passed through different zones of temperature. This whole process in kiln

usually covers 2 to 3 hours. Different temperature zones are as under:

Preheating

Zone

In

this zone, temperature is kept at 500 degree Celsius & usually the moisture

is removed & clay is broken into silica, aluminum oxide, iron oxide.

Decomposition

Zone

Temperature

is raised up to 800 degree Celsius. In this zone lime stone decomposes into

lime and CO2.

Burning

Zone

In

this zone temperature is maintained up to 1500 degree Celsius and the oxides

formed in above zones combine together and form respective silicate, aluminates

& ferrite.

Cooling

Zone

This

is last stage where the whole assembly cooled is up to 150 to 200 degree

Celsius.

Clinker

Formation

The

product which is obtained from the rotary kiln is known as the cement Clinker.

Clinker is usually in the form of greenish black or grey colored balls.

Grinding

the Clinker with Gypsum

The

Cement Clinker is then air cooled. The required amount of Gypsum (5 %) is

ground to the fine powder, and then mixed with the Clinker. Finally. cement is

packed in bags and then transported to the required site.

Setting

and Hardening:

When

ordinary Portland cement is mixed with water its chemical compound constituents

undergo a series of chemical reactions that cause it to set.

These

chemical reactions all involve the addition of water to the basic chemical

compounds. This chemical reaction with water is called "hydration".

Each

one of these reactions occurs at a different time and with different rates.

Addition

of all these reactions gives the knowledge about how Ordinary Portland cement

hardens and gains strength. Those compounds and their role in hardening of

cement are as under:

Tricalcium

silicate (C3S): Hydrates and hardens rapidly and is largely responsible for

initial set and early strength. Ordinary Portland cements with higher

percentages of C3S will exhibit higher early strength.

Dicalcium

silicate (C2S): Hydrates and hardens slowly and is largely responsible for

strength increases beyond one week.

Tricalcium

aluminate (C3A): Hydrates and hardens the quickest. It liberates a large amount

of heat almost immediately and contributes somewhat to early strength.

Gypsum

is added to Ordinary Portland cement to retard C3A hydration. Without gypsum,

C3A hydration would cause ordinary Portland cement to set almost immediately

after adding water.

Tetracalcium

aluminoferrite (C4AF): Hydrates rapidly but contributes very little to

strength. Most ordinary Portland cement color effects are due to C4AF.

Uses

of OPC (Ordinary Portland Cement):

It

is used for general construction purposes where special properties are not

required. It is normally used for the reinforced concrete buildings, bridges,

pavements, and where soil conditions are normal.

It

is also used for most of concrete masonry units and for all uses where the

concrete is not subject to special sulfate hazard or where the heat generated

by the hydration of cement is not objectionable.

It

has great resistance to cracking and shrinkage but has less resistance to

chemical attacks.

Tests On Ordinary Portland Cement

1.

Fineness test

2.

Soundness test

3.

Setting time test

4.

Strength tests

·

Tensile strength

test

·

Flexural strength

test

5.

Specific gravity

test

6.

Consistency test

7.

Heat of hydration

test

8.

Loss of ignition

test

Heat

of hydration test

Loss

of ignition test

Haseeb

Jamal. I am a Civil Engineer,

graduated from University

of Engineering and Technology, Peshawar, Pakistan in 2010. I also

have a PG-Diploma in Disaster Management and

MS in Urban

Infrastructure Engineering (In Progress). My expertise include civil

related softwares like AutoCAD,

SAP2000, MS Project, Primavera, MS Office and GIS. My technical skills include

project management, monitoring and evaluation, structural assessment, disaster

risk management, Quantity survey, land survey, material testing, site

management and technical writing. I am trained in writing project progress

reports as well as proposals and concept papers. I have also received advanced

training on surveying, proposal writing, Monitoring and Evaluation of projects

as well as organizations.

I have worked as Project

Engineer at National Research and Development Foundation, Peshawar and

CENCON Associates. I also worked with Spectra Engineering Solutions as Senior

Civil Engineer in monitoring of World Bank and UNDP funded projects all

over Khyber Pakhtunkhwa and FATA. Currently, I am working as Deputy

Manager Development at NayaTel, Peshawar.

No comments:

Post a Comment