..........................................................................................................................................................

By: Haseeb Jamal

Artificial (kiln) Seasoning

Artificial

methods of seasoning timber

Kiln

drying of lumber is perhaps the most effective and economical method available.

Drying rates in a kiln can be carefully controlled and defect losses reduced to

a minimum. Length of drying time is also greatly reduced and is predictable so

that dry lumber inventories can often be reduced. Where staining is a problem,

kiln drying is often the only reasonable method that can be used unless

chemical dips are employed.

Kilns

are usually divided into two classes:

1.

Progressive

2.

Compartment

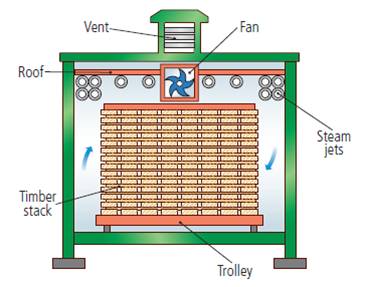

Both

methods rely on the controlled environment to dry out the timber and require

the following factors:

· Forced air circulation by using large fans, blowers,

etc.

· Heat of some form provided by piped steam.

· Humidity control provided by steam jets.

Amount

and Duration of Air, Heat and Humidity depends upon:

1.

Species

2.

Size

3.

Quantity

1. Progressive

Seasoning:

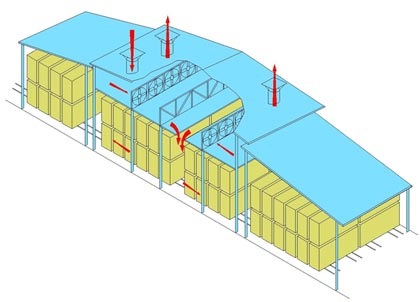

In

the progressive kiln, timber enters at one end and moves progressively through

the kiln much as a car moves through a tunnel.

Temperature

and humidity differentials are maintained throughout the length of the kiln so

that the lumber charge is progressively dried as it moves from one end to the

other.

Progressive

kilns may be further subdivided into natural draft kilns in which heated air is

allowed to rise through the material by natural convection, and forced draft

kilns in which fans are employed to force the air through the wood.

A

progressive kiln has the stack on trolleys that ‘progressively’ travel through

chambers that change the conditions as it travels through the varying

atmospheres.

Progressive Kiln

The

advantage of this system, although

much larger, has a continuous flow of seasoned timber coming off line.

A

number of commercial processes for seasoning of timber are available, the most

common of which is kiln-drying.

Kiln

seasoning accelerates the process of seasoning by using external energy to

drive the moisture out.

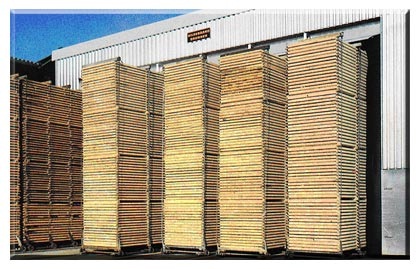

The

timber is stacked in much the same way as it is for air drying, and is placed

inside a chamber in which the conditions can be varied to give best seasoning

results.

Air

is circulated around the charge (stacked timber) and the temperature and

humidity can be varied to give optimum drying.

Each

species has different cell characteristics and therefore requires different

drying schedules.

Typically,

the timber may be in the kiln for a period of between two days to one week.

Generally,

it is not feasible to kiln-dry structural timber in thicknesses greater than 45

mm, although there are limited amounts of 70 mm thick kiln-dried softwood

members in the market place.

All

untreated structural pine and some commercial hardwoods are seasoned, mostly

using kilns that are often heated by sawmill by-products or gas.

Plenty

of research is continually being done to determine kiln drying schedules for

different species.

An

optimum schedule will remove the moisture as quickly as possible, with the

minimum quantity of introduced energy, and giving minimum damage to the dried

timber.

After

kiln seasoning, there is often some damage to cells near the surface of the

wood. (All of the moisture passes through those cells.)

They

have in fact collapsed, but can easily be ‘pumped back up’ in a reconditioning

chamber. This chamber introduces steam for a period and puts some moisture back

into the outer cells and removes the effect of seasoning collapse.

Hard

woods have closed cell structure, so take more time in being seasoned and

dried.

Conventional

kiln-drying for hardwoods uses temperatures well below the boiling point of

water. This avoids damage to the wood

fibres which, if the seasoning is not properly controlled, can experience loss

of strength.

In

seasoning hardwoods, the process is slow and can be economically undertaken by

first of all air-drying or partially seasoned for a period which can be

anywhere from 3 to 9 months, depending upon the thickness of material, the

ambient temperature and humidity and the species.

The

partial seasoning process can be accelerated for some hardwoods by using

fan-forced pre-drying in a controlled (but not kiln) environment, to reduce the

lead time for kiln-drying to 20 to 30 days.

Once

the sawn hardwood material reaches fibre saturation point or slightly below (at

a moisture content of about 20% to 25%), it is then placed in kilns usually for

up to 10 - 14 days (depending upon the thickness of the sawn timber) in order

to bring the moisture content down to between 10% and 15%.

This

drying process must be strictly controlled and monitored in order to avoid

drying degrade.

..

..

The

amount and duration of air, heat and humidity again depends on species, size,

quantity, etc.

2. Compartmental

Seasoning:

A

compartment kiln is a single enclosed container or building, etc.

The

timber is stacked as described above and the whole stack is seasoned using a

programme of settings until the whole stack is reduced to the MC required.

Compartment

kilns differ from progressive kilns in that the timber is loaded into the kiln

and remains in place throughout the drying process.

Compartment

kilns are usually smaller than progressive kilns, and because of their

construction the temperature and humidity conditions within them can be closely

controlled.

Consequently,

they are often used to dry expensive material or woods which are difficult to

dry.

Circulation

may be either forced or natural just as with progressive kilns. Drying

conditions cannot be controlled as closely in natural draft compartment kilns,

however, as in forced draft kilns, and the rate of drying is also slower.

For

these reasons kilns built today are of the forced draft type and many of the

old natural draft types have been converted.

Haseeb Jamal. I am a Civil Engineer, graduated from University

of Engineering and Technology, Peshawar, Pakistan in 2010. I also

have a PG-Diploma in Disaster Management and

MS in Urban

Infrastructure Engineering (In Progress). My expertise include civil

related softwares like AutoCAD,

SAP2000, MS Project, Primavera, MS Office and GIS. My technical skills include

project management, monitoring and evaluation, structural assessment, disaster

risk management, Quantity survey, land survey, material testing, site

management and technical writing. I am trained in writing project progress

reports as well as proposals and concept papers. I have also received advanced

training on surveying, proposal writing, Monitoring and Evaluation of projects

as well as organizations.

I have worked as Project

Engineer at National Research and Development Foundation, Peshawar and

CENCON Associates. I also worked with Spectra Engineering Solutions as Senior

Civil Engineer in monitoring of World Bank and UNDP funded projects all

over Khyber Pakhtunkhwa and FATA. Currently, I am working as Deputy

Manager Development at NayaTel, Peshawar.

No comments:

Post a Comment