..............................................................................................................................................................

Biogas

A Beginners Guide – Home to

Commercial Digester Systems

anaerobic-digestion.com

What

is Biogas?

Biogas

is generated during anaerobic digestion (AD) when microorganisms break down (by

eating it) organic materials in the absence of air (or oxygen).

Biogas

is mostly methane (CH4) and carbon dioxide (CO2), with very small amounts of

water vapor and other gases. The carbon dioxide and other gases can be removed,

leaving only the methane.

Methane

is the primary component of natural gas. The material that flows out after

anaerobic digestion happens is called “digestate.”

Digestate

is a wet mixture that is usually separated into a solid and a liquid. Digestate

is rich in nutrients and can be used as fertilizer for crops.

In

the process of anaerobic digestion, as mentioned above, the bacterial breakdown

of organic materials in the absence of oxygen produces biogas.

The

process occurs in the following four steps:

· Hydrolysis: large polymers are broken down by enzymes

· Acidogenesis: acidogenetic fermentations are most

important, acetate is the main end product. Volatile fatty acids are also

produced at this stage along with carbon dioxide and hydrogen.

· Acetogenesis: breakdown of volatile acids to acetate

and hydrogen.

· Methanogenesis: acetate, hydrogen are converted to

methane and carbon dioxide.

And,

the result is the sustainable renewable energy source (sometimes also spelled

as) “bio-gas”.

Why

is Biogas Important?

Biogas

is important because it is a rare and badly needed commodity in these times of

climate change. it’s important as a source of green and clean energy. It’s also

important in other ways as well.

a) It Can be a Significant Contributor to Reducing

Global Carbon Dioxide Emissions

In

December 2019 the World Biogas Association presented the UNFCCC with an

industry commitment.

Major

biogas industry players committed to delivering a 12% reduction in global

greenhouse gases emissions by 2030 provided world governments help unlock the

sector’s potential.

b) An Untapped Material Supply with Scope to Enlarge

As

we said at the start, it is made from biological breakdown of organic matter.

There is a huge quantity of waste organic material available that can be used.

The

waste organic material which can be used includes feed materials (feedstocks)

such as :

· all kinds of animal dung/ manure,

· kitchen waste, and waste from commercial food processing

· dead plants etc. including the parts of food crops

which are not food, such as the stems and leaves.

The

important point about this is that it can be used as gaseous fuel. Methane is a

gas which provides good caloric values when used as fuel.

What

is more, at the moment less than one tenth of the available waste organic

matter which could be easily be digested to make biogas is being used.

c) It’s Already a Cooking Fuel in India and Similar

Nations

Biogas

produced from the anaerobic disintegration of manure in small-pits in India is

called Gobar Gas. Many other developing nations, including China, also make

their biogas this way

The

gobar gas is also very important because it is estimated that over two million

households in India already make their own gobar gas for cooking.

They

do do this easily using dung from their own cattle. It is popular source of

fuel in many parts.

d) It Recycles as Part of a Circular Economy

Anaerobic

digestion delivers two types of recovery from organic waste in a virtuous

carbon circle:

Agronomic waste recovery: with the production of compost, and energy in the

form of biogas, electricity or heat. This technology is widely used across

Europe and is gaining momentum all around the world.

It provides an

answer to one of the current challenges facing the farming sector.

The sector

must now design new models of production taking into account environmental

constraints, big reductions in carbon emissions, while still improving competitiveness

and feeding the ever-rising population.

Industrial and Commercial waste recovery: again, with the production of compost and energy but

more wide-ranging types of organic waste, from the likes of the food and

beverage industries.

Plus, waste

from municipalities, such as green waste from parks and gardens and the

byproducts from wastewater treatment plants.

Unlike

incineration, precious organic material is retained to provide fertilizers and

soil improver which is a very important function.

If the output

from a biogas plant is made into charcoal (char) it can be put back on the land

to improve soil quality while also acting as carbon storage (also known as

carbon sequestration).

What

is the Cost of the Source of Biogas Energy

Often

there are no charges for this energy source. A large proportion of the raw

materials, in particular manure and plant residues, are generally available

free of charge.

There

is no transport needed when the digester is built on-farm.

Using

“waste” raw materials has the greatest economic potential for the production of

biogas.

These

materials may even be more cheaply treated using AD plants, where taxes are

charged for disposing that material to landfill.

Compare

that with the cost of mining fossil fuels for energy!

What

is Biogas Used for?

It

is a great gas to use for domestic cooking and that’ what gobs gas is used for

as described earlier.

In

agriculture it can be used on-farm for heating farm buildings and the

farmhouse. Any excess can be used for generating electricity which can be sold

for an income.

Biogas

can be used for electricity production at sewage works, in a CHP gas engine,

where the waste heat from the engine is conveniently used for heating the

digester.

If

purified (upgraded) it can be compressed to replace compressed natural gas for

use in vehicles, where it can fuel an internal combustion engine.

Or

it can be used in fuel cells. in both the later uses it is a much more

effective displacer of non-renewable carbon dioxide than the normal use in

on-site CHP plants.

What

is Biogas Made of

The

composition of biogas varies depending upon the substrate composition, as well

as the conditions within the anaerobic reactor (temperature, pH, and substrate

concentration).

Landfill

gas is a form of this gas. It typically has methane concentrations around 50%.

Digester

gas produced using advanced waste treatment technologies can produce biogas

with 55%–75% methane, which for reactors with free liquids can be increased to

80%–90% methane using in-situ gas purification techniques.

What

is a Biogas Generator?

A

biogas generator is any machine, mechanical plant and equipment that converts

waste into clean energy!

Many

people make their own Biogas Generator to produce their own “natural” gas.

For

example, you can do it in a way that transforms grass clippings, food waste and

livestock manure into renewable biogas energy with a homemade biogas generator

What

is Biogas Production?

It’s

the making of this bio-fuel.

Most

biogas production takes place in processing facilities (plants) which rely on

anaerobic digestion, a fermentation process in which waste is digested by

microbes to produce a predominantly methane gas (biogas).

Almost

any organic waste can be used in the process, though factors such as ph and

temperature affect the gas production.

The

Working of Biogas Plants

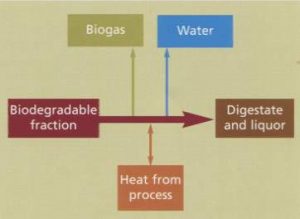

During

the process, the micro-organisms transform biomass waste into biogas (mainly

methane and carbon dioxide) and digestate.

Higher

quantities of biogas can be produced when the wastewater is co-digested with

other residuals from the dairy industry, sugar industry, or brewery industry.

For

example, while mixing 90% of wastewater from beer factory with 10% cow whey,

the production of biogas was increased by 2.5 times compared to the biogas

produced by wastewater from the brewery only.

The

Types of Biogas Plants

Common

biogas plant types can be differentiated according to methods of substrate

feed, biogas collecting methods, materials used for their construction,

horizontal or vertical digester position, underground and above-ground digester

location and according to additional equipment used.

There

are many different types. Here are some examples:

Batch

biogas plants

Wet

Process Batch Digester (for example a laboratory trial digester use to find

likely gas output/ optimum substrate retention time)

Dry

Digester (Tunnel)

Vertical

DRANCO (DRy ANaerobic COmposting) process

Continuous

load plants

· Single Stage Continuous Stirred Tank Reactor (CSTR)

· Two Stage CSTR

· Plug Flow Reactor

· Upward Anaerobic Sludge Blanket (UASB) Reactor

· Anaerobic Lagoon

The

Biogas Digester

A

“digester” is simply a biogas plant by another name. sometimes the digester may

be referred to as just the big tank reactor where fermentation takes place.

The

Importance of Bio-gas

The

importance of biogas lies in its ability in converting organic waste into

energy.

Not

only that it utilizes nature’s elegant tendency to recycle substances into

productive resources.

It’s

generation recovers waste materials that would otherwise:

· pollute landfills;

· be left around to make methane to further raise the

global temperatures

It’s

also important as it can treat waste on-site enabling the output nutrients to

be put back into the land.

Moreover,

its usage does not require fossil fuel extraction to produce energy.

Biogas

Advantages

Biogas:

1. Is Eco-Friendly

2. It’s Generation Reduces Soil and Water Pollution

3. It’s Generation Produces Natural Organic Fertilizer

4. It’s a Simple and Low-Cost Technology That

Encourages A Circular Economy

5. It’s a Healthy Cooking Alternative For Developing

Countries.

Disadvantages

of Biogas

· New Technological Advancements needed to make these

plants easier to operate and lower costs

· Contains Impurities

· Effect of Temperature on it’s Production means they

work best in hotter climates unless heavily insulated and heated against the

cold

· Less Suitable For Dense Metropolitan Areas.

Biogas

Yield

The

variables that can make a difference to the yield of bio-gas include:

· the feedstock you use (crop, waste, manure etc. )

· the length of time left in the digester

· the mix of different organic materials

· the efficiency of reactor mixing

· the pH of the reactor

· the build-up of inert materials such as grit, sand and

other unwanted materials such as inadvertent plastics which enter the reactor

tanks.

· the presence or absence of importance of trace

nutrients.

If

your feedstock has been left in storage for a long amount of time it may have

already started breaking down. Tables are available which show the potential

bio-gas yields of common feedstocks.

The

Methane Content

The

gas has a composition which is usually 50% to 80% methane and 20% to 50% carbon

dioxide with traces of gases such as hydrogen, carbon monoxide, and nitrogen.

In

contrast, natural gas is usually more than 70% methane with most of the rest

being other hydrocarbons (such as propane and butane) and traces of carbon

dioxide and other contaminants.

Biogas

Boiler Design

Biogas

can then be used to generate electricity, as a boiler fuel for space or water

heating.

Depending

on the design of the boiler the raw gas may, or may not, first be upgraded to

natural gas pipeline quality.

If

upgraded the biomethane produced can be used to fuel any standard boiler

designed for pipeline distributed “natural gas”.

Steam

boilers are available which can be operated with different liquid and gaseous

fuels, such as natural gas, fuel oil, biogas, and with multi-fuel firing units.

Biogas

Heating System

A

biogas heating system is created when the hot water from a gas-engine

(generator) jacket, and generator or exhaust gas heat exchanger, is distributed

through a network of pipes and is used for home, farmhouse, drying room, barn,

factory, warehouse, or work-space heating.

Sometimes

the heating system will be provided heat from a bio-gas fueled boiler

AD

Plant Cost

Although

a number of cost calculators are offered on websites, very little data on

biogas cost is published.

The

truth is that these facilities vary so much that to put a price tag on them

isn’t possible without deciding first on a design, and from that estimating

tank sizes etc. Only once site specifics are known is it reasonable to price

these AD Plants.

Capital

costs for a larger ad facility (50,000 tons per year) are expected to be over

$20 million.

Small

home digesters may be bought for about $500.

What

is its Future?

The

possibilities of increased use of anaerobic digestion as an effluent treatment

process depend upon the introduction of improved digester designs at:

· small scale and particularly domestic scale reactor

designs need improving to make them cheaper and capable of delivering maximum

energy yields

· large scale plants need everything needed at the small

scale, plus government support to discourage those that would just throw their

waste in a big hole at a landfill site!

Limitations

concerning thermodynamic efficiency, scrubbing costs, flammability,

compress-ability and storage are also hampering the use of AD plants.

Despite

all this communities and governments are moving ahead with developing anaerobic

digestion technology.

The

overriding concern now developing is the imperative of reducing global warming.

Anaerobic digestion and biogas has a unique role to play in that, and the

quicker that is realized the better.

https://youtu.be/La6yXYwVq3A

The potential for anaerobic

digestion, and the benefits of the biogas process are massive. Discover

mankind's sustainable renewable energy future here! This website is an

independent venture, by people who are simply fascinated by the

subject (read About Us). We

want to help more people see our vision for a vibrant low-carbon future,

and become part of the AD technology movement. You are very welcome

to spend time on this website, and we hope that you will get involved by

commenting, and maybe even joining our campaign for better AD awareness, as

well.

|

| Anaerobic digestion schematic |

No comments:

Post a Comment