...................................................................................................................................................

How Does Temperature Gun Work?

Vikas

Shukla

engineeringinsider.org

When you

think about a thermometer, you probably picture a device with some kind of

probe that is placed into the object being measured.

Whether

it is a thermometer that you place under your tongue to take your own temperature, or

a food thermometer that you push into a piece of meat to make sure it is done,

probe-style thermometers have long been a standard.

However,

there are plenty of other options on the market today, and infrared

thermometers are among the most exciting and useful styles to consider.

Offering

ease of use and accurate readings, there is a lot to like about an infrared

option.

An

infrared thermometer commonly called temperature gun these days, may be called

for anytime the surface temperature of an object needs to be determined.

Obviously,

since the infrared beam is only bouncing off of the surface, this is not a

suitable method of measurement when the interior temperature of an object needs

to be found.

There are

nearly countless applications, and this technology is already used in a wide

range of industries.

Checking

the level of heat coming from a piece of equipment, for instance, is a good way

to check for trouble that may be occurring on the inside.

If the

equipment is hotter than it should be on the surface, there is a good chance

that something is going wrong internally.

Considering

how many various infrared thermometer models are available today, and how

accurate they have become, it is easy to see why they are a popular choice in a

number of industries.

A SIMPLE PRINCIPLE

While the

technology that makes these thermometers work is certainly complex, the concept

itself is rather simple.

Everything

that has mass emits some amount of energy, and that energy is emitted in the

form of heat.

Everything

that has mass emits some amount of energy, and that energy is emitted in the

form of heat.

Since

there is heat being emitted by any object, an infrared thermometer can use the

difference between the IR rays coming off of the object and the surrounding

environment to determine the surface temperature of the object itself.

The IR

thermometer works by focusing light that is coming from the object in the form

of IR rays and funneling that light into a detector – which is also known as a

thermopile.

It is in

the thermopile that the IR radiation is turned into heat which is then

turned to electricity, which is then measured.

It is

ultimately the amount of electricity that is generated by the rays being put

out by the object in question that will provide a reading that is displayed on

the thermometer.

The

reading will be generated in a manner of seconds, meaning an infrared

thermometer is a quick way to gather a temperature reading in a number of

different scenarios.

WHY INFRARED?

There are

a number of reasons why you should consider choosing infrared technology for

your temperature reading needs.

When

shopping for a thermometer to add to your stable of equipment, consider

purchasing a quality infrared thermometer for some of the following reasons.

1. Accuracy. Obviously, you need to be confident that you

are getting an accurate reading from your thermometer when you put it to use,

and infrared models have a great reputation for accuracy. The technology used

in these products is simple yet advanced, and you should be able to rely on the

information that you receive – provided that the thermometer is used in the

right way.

2. Safety. One of the great things about being able to

check on temperature remotely is that you don’t actually need to touch the

object in question.

If you are trying to take

the temperature of a particularly hot item, you won’t need to place your hand,

or even another piece of equipment, onto the hot surface.

Just by aiming your IR

thermometer at the object you wish to measure, you can get all of the

information you need without putting yourself at risk.

3. Contamination prevention. Another benefit to the remote

measuring system is avoidance of contamination.

This is particularly

important within the food service world, but it applies in other

applications as well.

Since you don’t need to

touch the item that you are measure, you won’t need to worry about

contaminating that product with the probe of a thermometer.

Rather than having to

make sure that all of your temperature measuring equipment is properly

sterilized prior to each use, you can simply point the IR gun at the item being

measured and forget any worries about contamination problems.

4. Durability. You want an Infrared Thermometer that is

tough enough to stand up to the demands of the jobsite, workshop or just being

bounced around in your toolbox.

There are certainly more

than three advantages to using infrared, but the three listed above are some of

the most important.

Additionally, the cost of

this technology has come down in recent years, meaning you can access this

great method of temperature measurement for a significantly lower cost than it

would have required just a few short years ago.

GETTING IN RANGE

It is

important to pick an infrared thermometer that is rated to measure items within

the temperature range that will be applicable to your uses.

Every IR

unit on the market today is rated for a specific range of temperatures, and it

will not be accurate if you are trying to measure items that fall outside of

that range.

Therefore,

before picking out an infrared thermometer, you are going to need to think

carefully about what you will be measuring and the expected temperature ranges

for those items.

As an

example, you may find one unit that is capable of measuring temperatures from

as low as -40F all the way up to 428F while another unit ranges from -4F all

the way up to 626F.

Most

units will be suitable for covering moderate temperatures, but you need to

carefully check the specs on any infrared thermometer that is being purchased

for the purpose of measuring extremely cold or extremely hot items.

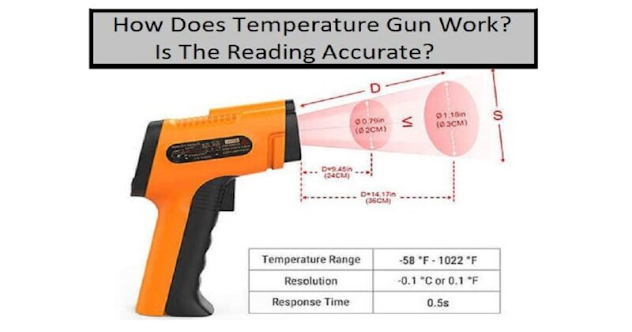

DISTANCE-TO-SPOT RATIO

Another

important element of IR thermometers is the distance-to-spot ratio that they

offer.

Commonly

available ratios include 4:1, 8:1, 30:1, and even 50:1.

Commonly

available ratios include 4:1, 8:1, 30:1, and even 50:1.

What does

the distance-to-spot ratio mean?

It refers

to the distance you can be from the object that is being measured while still

receiving an accurate reading.

So, the

bigger the ratio, the farther away you can stand from the target object while

still getting a good reading.

For

example, with a 30:1 ratio you can be standing 30 inches away from your target

and still accurately measure an area of 1 square inch.

To

measure that same area with an 8:1, you would need to be standing 8 inches

away.

Higher

distance-to-spot ratios are usually found on models with very high temperature

ranges, allowing you stand a safer distance away from the heat source.

Naturally,

this is another element that needs to be factored in when you are picking out

an IR thermometer model.

Are you

going to be right next to the objects that you are measuring, or will you need

to keep your distance for safety reasons?

If you

are going to be back a significant distance, make sure the model you pick out

is capable of remaining accurate thanks to a large distance-to-spot ratio.

Although

infrared thermometers are limited to taking surface temperature readings, they

remain a valuable tool that is used by professionals in a variety of

industries.

When you

are picking out your own IR unit, be sure to pay close attention to both the distance-to-spot

ratio, as well as the temperature range that is offered by that model.

Once you

do receive your thermometer, read all of the instructions carefully and use the

unit in accordance to the manufacturer’s recommendations in order to get the

most accurate readings possible.

While not

the perfect tool for every temperature measuring job, there is a good chance

you will find plenty of occasions to put an IR thermometer to work for you.

Does Temperature Gun Give Accurate

Temperature?

Research has shown that, when

used correctly, infrared or no-contact thermometers (temperature gun) are just

as accurate as oral or rectal thermometers.

No-contact thermometers are

popular among pediatricians, as kids often squirm around when trying to get a

temperature read, but it also holds true in mass temperature screenings.

The device offers safety to both

parties while providing a quick and accurate read.

Of

course, when available, an internal thermometer is the gold standard in

healthcare.

But

due to COVID-19 and the need to quickly mass test, a no-contact thermometer has

become the standard.

The operator needs to follow the

device’s protocol and it won’t pick up a fever on someone who has taken

fever-reducing medication.

But with many establishments now

requiring temperature checks, these hand-held thermometers are proving to be

safe, quick and accurate while helping to reduce the spread of coronavirus.

https://engineeringinsider.org/how-does-temperature-gun-work-is-the-reading-accurate/

No comments:

Post a Comment