...............................................................................................

Everything You Need to Know

Family Handyman

PEX supply pipe is

the biggest revolution in plumbing since the flush toilet, and in this article

we’ll answer the most common questions homeowners have about it and also give

you some tips for working with it.

Which

is Better – PEX or Copper?

PEX (cross-linked polyethylene) has several advantages

over copper:

·

PEX is cheaper than copper. Half-inch

PEX tubing costs about a third the price of copper. Some of the savings will be

offset by the need for a special tool to install the fittings, but if you’re

doing a medium to large plumbing job, you’ll usually save by using a PEX supply

instead of copper.

·

PEX fittings are faster to install

than copper. If you use a manifold and ‘home-run’ system, it’s like running a

garden hose to each fixture — super fast and easy. But even if you install PEX

fittings in a conventional main line and branch system, the connections are

quicker to make than soldering copper.

·

A PEX supply won’t corrode like

copper. If you live in an area with acidic water, copper can corrode over time.

A PEX supply is unaffected by acidic water and is therefore a better choice in

these areas.

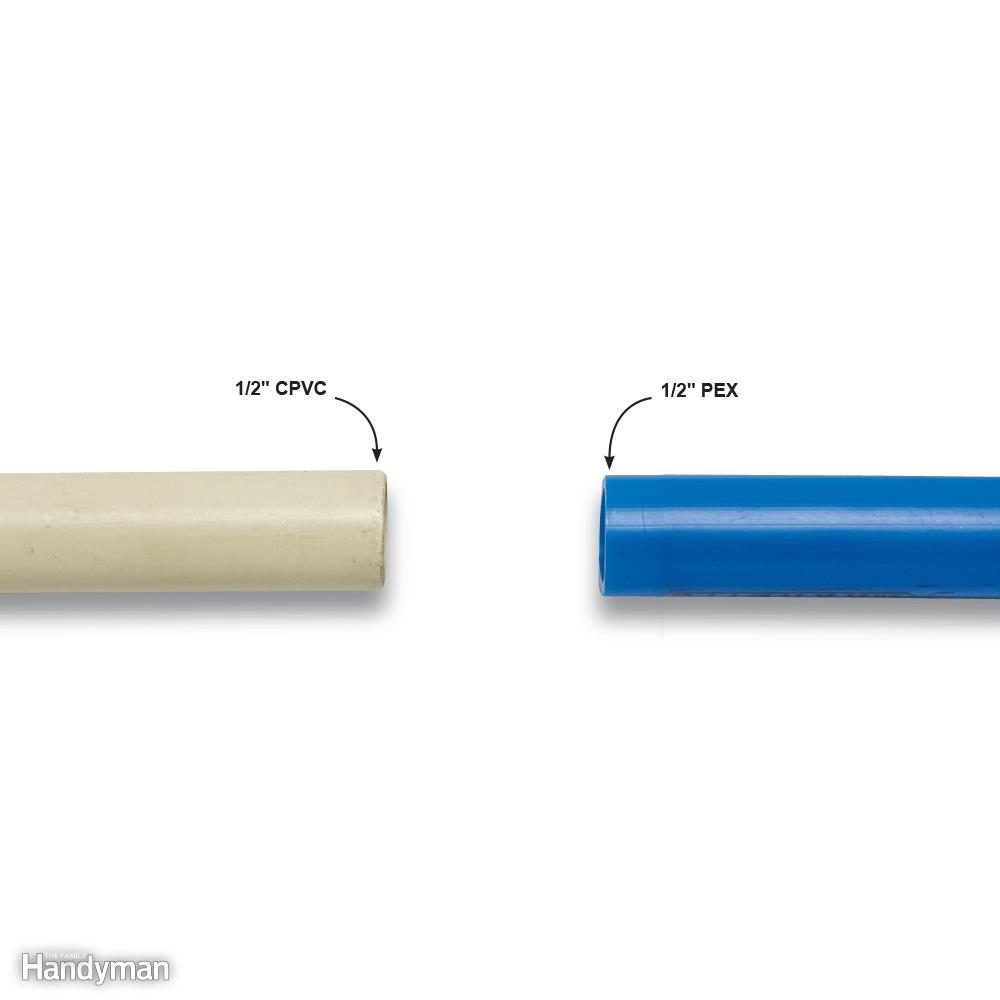

What

About PEX vs. CPVC?

A PEX supply and CPVC cost about the same. But there are a

few reasons why a PEX supply may be a better choice.

First, a PEX supply doesn’t require glue, which means you

don’t have to work in well-ventilated spaces or wear a respirator.

PEX supply is less likely than CPVC to burst if it

freezes.

Also, since PEX supply is more flexible and is available

in long lengths, it can work better for ‘fishing’ through walls in remodeling

situations.

Do

I Need Special Tools?

No. You can use stab-in or

compression fittings to make the connections. But they’re too expensive to be

practical on large projects.

For most PEX supply jobs, you’ll want

to invest in a special tool to make connections.

There are several PEX supply

connection methods, but only two that are affordable enough to be practical for

DIYers: crimp rings and cinch clamps.

Crimp rings are a band of metal,

usually copper, that you slip over the fitting and compress with a crimp ring

tool.

The main drawback to the crimp ring

method is that you’ll need either separate crimping tools for 1/2-in. and

3/4-in. fittings, or a universal tool with a swappable insert (not shown). This

adds a little up-front cost to this method. A combo kit with interchangeable

crimp jaws starts at about $100.

Cinch clamps work more like the

traditional band clamps you’re probably familiar with.

You slip the cinch clamp tool over

the protruding tab and squeeze to tighten the cinch clamp. The same tool works

for all sizes of cinch clamps.

Cinch clamp tools start at about $40.

We like the one-handed version shown in the photo because you can hold the ring

in place with one hand while tightening it with the other.

The only other special tool you need

is a scissors-like cutter for the tubing.

Check out Milwaukee Tools’ ProPex

Cordless Pex Tool in this Stuff We Love video to learn more about what tools

are out there.

How

Do I Splice PEX Fittings Into My Existing Pipe?

There are several

methods. The easiest is to cut out a section of plumbing pipe and slip in a

stab-in tee (left). SharkBite is one common brand of stab-in fitting.

This method doesn’t

require soldering, which can be a big time-saver. But check with your plumbing

inspector if you’re planning to bury this connection in a wall or ceiling.

Some areas don’t

allow stab-in fittings to be concealed.

Another method is

to solder in a tee and a PEX supply adapter. Then slip the PEX supply tubing

over the adapter and attach it with your chosen connection method (right).

You can also use a

stab-in tee to connect PEX fittings supply to CPVC. Read the label to find the

compatible fitting.

Do I Have to Use Manifolds with PEX?

No. You can install PEX fittings supply just like you

would other pipe, with main lines and branches to each fixture. But you lose a

lot of the benefits of PEX supply with this system since it requires so many

fittings.

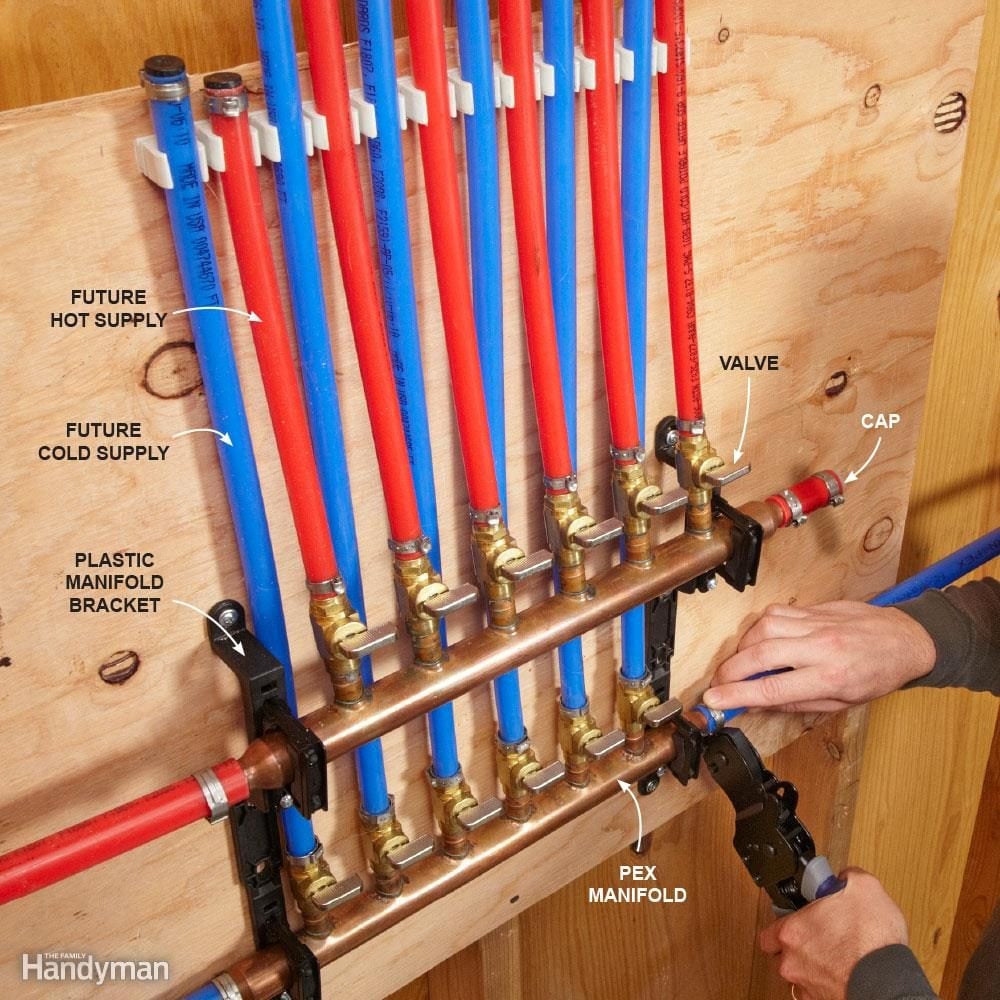

With the home-run system, you install a manifold in the

utility room or some area that’s close to the main water line and water heater,

and run a separate PEX supply tube to each fixture as shown above.

This system uses more tubing but is fast and only requires

two connections: one at the manifold and another at the fixture end.

You can also use a hybrid system where you run 3/4-in. hot

and cold lines to a set of fixtures — for example, a bathroom — and install a

smaller manifold behind an access panel. Then make short runs of 1/2-in. PEX

water line supply tubing to each fixture.

Manifolds look intimidating, but they

actually simplify plumbing runs and reduce possible leaks by eliminating the

need for tees and other fittings between the main supply line and the fixture.

Does

it Meet Code?

There is no unified national plumbing code. Before

starting your PEX supply plumbing job, check with your local inspector for

specific local requirements.

Do

I Have to Use Red for Hot and Blue for Cold?

PEX supply comes in red and blue colors to help you keep

track of the hot and cold lines. You can use white PEX supply for everything if

you prefer.

Is

PEX Reliable?

PEX supply has been used for decades in other countries,

where there are thousands of homes with 30-year-old, leak-free PEX. Most of the

problems with PEX supply systems (in the United States and elsewhere) have been

caused by sloppy installation or faulty fittings rather than the tubing itself.

Can

I Connect PEX to my Water Heater?

PEX can’t be directly connected to a water heater. First

extend a pipe 18 in. from your water heater and connect the PEX supply to the

pipe.

Which

Tubing Should I Use for Interior Water Lines?

For water lines, there are three PEX supply grades: PEX-A,

PEX-B and PEX-C. They’re manufactured differently, PEX-A being slightly more

flexible.

If you’re ordering online, go ahead and spend a few cents

extra for PEX-A. But don’t go running around town looking for it; the

difference isn’t that big.

The plumbers we talked to would be willing to use any of

the three types in their own homes. PEX is also popular for in-floor radiant

heating systems, for which you need PEX supply tubing with an oxygen barrier.

How

Do I Connect PEX to my Plumbing Fixtures?

There are several methods. If the connection will be

visible, like under a wall-hung sink, and you would prefer the look of a copper

tube coming out of the wall, use a copper stub-out (left).

You can connect a compression-type shutoff valve to the

1/2-in. copper stub-out and then connect your fixture.

In areas that are concealed, like under a kitchen sink or

vanity cabinet, you can eliminate a joint by running PEX supply directly to the

shutoff valve.

Use a drop-ear bend support to hold the tubing in a tight

bend (right). There are several types of shutoff valves that connect directly

to PEX.

If you’re using a manifold system

with valves, you may not need to install a shutoff valve at the fixture. Ask

your plumbing inspector.

We recommend adding one, though. It

doesn’t raise the cost much and is more convenient than running downstairs to

shut off the water when a repair is needed.

What

About Expansion?

PEX supply expands and contracts more than copper, so

don’t stretch it tight. Let it droop a little between fasteners. On long runs,

it’s a good idea to install a loop as shown to allow for contraction.

Another advantage of the loop is that if you mess up and

need a little extra tubing, you can steal it from the loop.

Also, since PEX moves as it expands and contracts, make sure

to drill oversize holes through studs or joists so it can slide easily, and

don’t use metal straps to attach it. Use plastic straps instead.

Will

PEX Break or Split if it Freezes?

Probably not. Manufacturers are reluctant to say so, but

reports from the field suggest PEX supply can withstand freezing. You should

still protect the tubing from freezing, but since it can expand and contract,

it’s less likely to break than rigid piping.

What

if I Goof? Can I Take it Apart?

Sure — there’s a special tool for cutting off crimp rings,

and you can use side cutters to remove cinch clamps. But a rotary tool (Dremel

is one brand) fitted with a cutoff blade works great for cutting either type of

connector (see photo).

After you remove the crimp ring or cinch clamp and pull

the PEX supply from the fitting, cut off the end of the tubing to get a fresh

section for the new connection.

If you damage the fitting with the rotary tool, replace

the fitting rather than risk a leak.

No comments:

Post a Comment