.................

Turbidity

Water is clarified using the

processes of coagulation and flocculation, which remove suspended solids

(turbidity) from water by causing the suspended particles to aggregate into a

slime, that settles out of the water.

This technique is used in

treating wastewater, both industrial and treated sewage, from municipal

wastewater treatment plants.

It is also used, as a first

step, in treating raw water for industrial use, and in food and beverage

production.

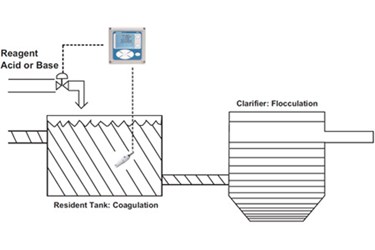

THE PROCESS

Coagulation uses salts such as aluminum sulfate (alum) or ferrous of ferric (iron) salts, which bond to the suspended particles, making them less stable in suspension, i.e., more likely to settle out.

Coagulation uses salts such as aluminum sulfate (alum) or ferrous of ferric (iron) salts, which bond to the suspended particles, making them less stable in suspension, i.e., more likely to settle out.

Flocculation is the binding

or physical enmeshment of these destabilized particles, and results in a slime

that is heavier than water, which settles out in a clarifier.

Flocculation agents are

natural synthetic polymers and synthetic organic polymers used to form the flocculant.

BACKGROUND

Water is clarified using the processes of

coagulation and flocculation, which remove suspended solids (turbidity) from

water by causing the suspended particles to aggregate into a slime, that

settles out of the water.

This technique is used in treating wastewater,

both industrial and treated sewage, from municipal wastewater treatment plants.

It is also used, as a first step, in treating

raw water for industrial use, and in food and beverage production.

THE PROCESS

Coagulation uses salts such as aluminum sulfate

(alum) or ferrous of ferric (iron) salts, which bond to the suspended

particles, making them less stable in suspension, i.e., more likely to settle

out.

Flocculation is the binding or physical

enmeshment of these destabilized particles, and results in a slime that is

heavier than water, which settles out in a clarifier.

Flocculation agents are natural synthetic

polymers and synthetic organic polymers used to form the flocculant.

pH EFFECTS

The salts used for coagulation form certain ions

in solution that are responsible for the coagulation action taking place.

However, the actual ions produced by these salts

depend upon the pH of the water sample. At varying sample pH values, the

coagulation process may suffer from less than optimum ions being formed in

solution.

pH that is too low may not allow the coagulation

process to proceed, while high pH can cause a coagulated particle to

redisperse.

The size of the coagulated particles is also

affected by pH, which, in turn, determines the density of the flocculated slime

and its tendency and rate of settling out.

The optimum pH for the coagulation and

flocculation process must be determined experimentally.

It is specific to each application and is

dependent upon the sample, the coagulation and flocculation agents used, the

desired clarity of the water, and the water’s end use.

pH MONITORING AND CONTROL

pH control of the sample prior to clarification

will also vary from application to application.

An industrial waste sample, for instance, may be

subject to wider pH variations, requiring stepwise pH control, while a raw

water sample for beverage production may only need small adjustments for minor

variations in pH and alkalinity.

Clarification is typically either the first step

in treating raw water, often river water or even city (potable) water, or the

last step that is prior to discharge of a wastewater sample.

As a result, the demands on the pH sensor, in

terms of temperature, pressure, and corrosion resistance, are minimal.

In certain cases, a pH measurement may be

required in the clarifier itself or after the clarifier for subsequent pH

adjustment.

The pH sensor may be exposed to the flocculant

(flocculating polymer and slime), which can form a tenacious coating on the pH

sensor.

Since the polymer coating is organic in nature,

it can be readily cleaned off using a solvent suitable for the polymer, but

which does not attack the sensor’s materials of construction.

The 396P TUpH™ Sensor, which resists the effects

of coating, can be used to maximize the time between required cleanings.

™ TUpH is a registered trademark of Rosemount Analytical, Uniloc Division.

No comments:

Post a Comment