The Virginia Cooperative

Extension (VCE) Offices in Virginia occasionally holds drinking water clinics

for well, spring and cistern owners as part of the Virginia Household Water

Quality Program. The VCE subsidizes the analysis cost for these clinics. Currently,

samples are analyzed for: iron, manganese, nitrate, lead, arsenic, fluoride,

sulfate, pH, total dissolved solids, hardness, sodium, copper, total coliform

bacteria and E. Coli bacteria at a cost of $49 to the well owner.

This is far from an

exhaustive list of potential contaminants, but with one or two exceptions these

are the most common contaminants that effect drinking water wells. These are

mostly the naturally occurring contaminants and common sources of

contamination: a poorly sealed well or a nearby leaking septic system, or

indications of plumbing system corrosion.

There are other

contaminants that can be found in ground water in certain regions that can

cause illness when exposed to small amounts over long periods of time. Uranium

is an example.

There are also

nuisance contaminants for which there is not an approved EPA methodology. Iron

bacteria is an example.

A through water

analysis should be performed before any treatment is considered to make sure

the selected treatment is necessary and appropriate.

Wells should be

tested annually for bacteria and every 1-3 years for other common contaminants

especially if you install treatment systems.

Groundwater is

dynamic and can change over time. And it is important to make sure that any

treatment is still appropriate and effective.

Water treatment systems are not an

install-and-forget piece of equipment. They are more of systems to maintain,

adjust and control to keep the water within ideal parameters.

Improperly treated

water can be as problematic as not treating water.

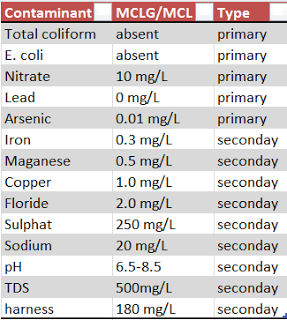

In order to determine if treatment is necessary, water test results

should be compared to a standard. The standard we use if the U.S. EPA Safe

Drinking Water Act in the list to the left.

There are primary and secondary drinking water

standards.

Primary standards are ones that can impact

health and from the list above include: coliform bacteria, E. coli and fecal

coliform bacteria, nitrate, lead, and arsenic.

Groundwater can

sometimes be contaminated from nearby or historic land use.

Before a home is

purchased, a much more comprehensive water analysis should be performed to

ensure that groundwater is not contaminated with hydrocarbons, solvents, fuels,

heavy metals, pesticides.

Coliform bacteria are

not a health threat itself - it is used to indicate other bacteria that may be

present and identify that a well is not properly sealed from surface bacteria.

The federal standard

for coliform bacteria is zero, but the federal standard allows that up to 5% of

samples can test positive for coliform during a month. New coliform standards

are anticipated to be promulgated shortly.

Fecal coliform and

E. coli are bacteria whose presence indicates that the water is contaminated

with human or animal wastes.

Disease-causing

microbes (pathogens) in these wastes can cause diarrhea, cramps, nausea,

headaches, or other symptoms.

.

These pathogens may pose a special health risk for infants, young children, and those with compromised immune systems.

.

These pathogens may pose a special health risk for infants, young children, and those with compromised immune systems.

However, people can

drink water contaminated with fecal bacteria and not notice.

If your water is

contaminated with coliform but not fecal coliform or E. coli, then you have a

nuisance bacteria problem and the source may be infiltration from the surface

from rain or snow melt.

Typical causes are

improperly sealed well cap, failed grouting or surface drainage to the well.

Shock chlorinate the

well, repack the soil around the well pipe to flow away from the well and

replace the well cap.

Then after the next

big rainstorm retest the well for coliform. If it is still present then a

long-term treatment should be implemented: using UV light, ozonation, or

chlorine for continuous disinfection.

If you have fecal

coliform in the well or E. coli, your well is being impacted by human or animal

waste.

If there is not a

nearby animal waste composting facility, then you are probably drinking water

from a failed septic system - yours or your nearest neighbors’.

To solve this

problem you need to either fix or replace the septic system that is causing the

contamination or replace the well. The failing septic systems can often be

identified by using tracer dyes.

While continuous

disinfection will work to protect you from fecal bacteria and E. coli, be aware

that if your well is being impacted by a septic system, then the well water

might also have present traces of all the chemicals and substances that get

poured down the drain.

Long term treatment

for disinfection, and micro-filtration should be implemented: using UV

light, ozonation, or chlorine for continuous disinfection and carbon filtration.

Anything that is

used for drinking should be further treated with a reverse osmosis systems or

micro membrane system that work by using pressure to force water through a

semi-permeable membrane.

This is the type of

system that is used to desalinate water. Large quantities of wastewater are

produced by reverse osmosis systems and need to bypass the septic system or

they will overwhelm that system creating more groundwater problems.

Reverse osmosis

systems produce water very slowly, a pressurized storage tank and special

faucet needs to be installed so that water is available to meet the demand for

drinking and cooking.

Nitrate can

contaminate well water from fertilizer use; leaking from septic tanks, sewage

and erosion of natural deposits.

The MCL for nitrate

is 10 mg/L. Infants below the age of six months who drink water containing

nitrate in excess of the MCL could become seriously ill from blue-baby syndrome

and, if untreated, may die.

Symptoms include

shortness of breath and a blue ting to the skin common in blue-baby syndrome.

The NO3 dissolves and moves easily through soil which varies seasonally and

over time as plants use up the nitrate over the summer.

Testing in the

spring will usually produce the highest levels. Nitrate may indicate

contamination from septic tanks, but do not boil the water- boiling water

reduces the water and actually INCREASES the concentration of nitrates.

So if your water is

being impacted by a septic system and you do not replace the well;

distillation, reverse osmosis, or ion exchange is necessary to control the

nitrate.

The

EPA guidance for sulfate is 250 ppm for taste.

Sulfates can clog plumbing and

stain clothing and excessive levels can have a laxative effect.

Hydrogen sulfide naturally

occurs in shale, sandstone, and near coal or oil fields.

Sulfate and hydrogen

sulfide are not regulated by the EPA for drinking water, they are a secondary

contaminant and though extremely unpleasant, harmless to animals, but not to

plumbing equipment.

There is a related

problem (for which there are limited methods of testing) of sulfur reducing

bacteria. According to the EPA, sulfur-reducing bacteria and sulfur-oxidizing

bacteria pose no known health risks.

Sulfur-reducing

bacteria live in oxygen-deficient environments such as deep wells, plumbing

systems, water softeners, and water heaters. These bacteria usually flourish in

hot water tanks and pipes.

Sulfate reduction

can occur over a wide range of pH, pressure, temperature, and salinity

conditions and produce the rotten egg smell and the blackening of water and

sediment by iron sulfide. Sulfate-reducing bacteria can cause the corrosion of

iron in pipes and water systems.

The treatment method

selected depends on many factors including the level of sulfate in the water,

the amount of iron and manganese in the water, and if bacterial contamination

also must be treated.

High concentrations

of dissolved hydrogen sulfide also can foul the resin bed of an ion exchange

water softener.

When a hydrogen

sulfide odor occurs in treated water (softened or filtered) and no hydrogen

sulfide is detected in the non-treated water, it usually indicates the presence

of some form of sulfate-reducing bacteria in the system.

Water softeners

provide an environment for these bacteria to grow. “salt-loving” bacteria, that

use sulfates as an energy source, may produce a black slime inside water

softeners.

If you have modest

sulfate, but no rotten egg smell, installing a water softening system may

create additional problems, especially if the system is not meticulously

maintained.

If you have a rotten

egg smell associated with the hot water and elevated levels of sulfate on the

cold water side, your hot water tank may be fouled with sulfur reducing

bacteria, or the tank’s corrosion control rod may be causing the sulfur to

react in the heated environment.

At naturally

occurring levels, iron and manganese do not present a health hazard.

However,

their presence in well water can cause unpleasant taste, staining and

accumulation of mineral solids that can clog water treatment equipment and

plumbing.

The standard

Secondary Maximum Contaminant Level (SMCL) for iron is 0.3 milligrams per liter

(mg/L or ppm) and 0.05 mg/L for manganese.

This level of iron and manganese are

easily detected by taste, smell or appearance.

In

addition, some types of bacteria react with soluble forms of iron and manganese

and form persistent bacterial contamination in a well, water system and any

treatment systems.

These organisms

change the iron and manganese from a soluble form into a less soluble form,

thus causing precipitation and accumulation of black or reddish black or reddish brown gelatinous material (slime).

All systems of

removing iron and manganese essentially involve oxidation of the soluble form

or killing and removal of the iron bacteria.

When the total

combined iron and manganese concentration is less than 15 mg/l, an oxidizing

filter is the recommended solution.

An oxidizing filter supplies oxygen to convert

ferrous iron into a solid form which can be filtered out of the water.

Higher concentrations of iron and manganese can be

treated with an aeration and filtration system.

This system is not

effective on water with iron/ manganese bacteria, but is very effective on

soluble iron and manganese.

Chemical oxidation can be used to remove high

levels of dissolved or oxidized iron and manganese as well as treat the

presence of iron/manganese (or even sulfur) bacteria.

The system consists

of a small pump that puts an oxidizing agent into the water before the pressure

tank.

The water will need about 20 minutes for oxidation to take place so

treating before a holding tank or pressure tank is a must.

After the solid

particles have formed the water is filtered.

The best oxidizing

agents are chlorine or hydrogen peroxide. If chlorine is used, an activated

carbon filter is often used to finish the water and remove the chlorine taste.

The holding tank or

pressure tank will have to be cleaned regularly to remove any settled particles.

Fluoride occurs

naturally in groundwater and in certain parts of Eastern Virginia there are

very high naturally occurring levels.

Fluoride is a primary water contaminant

and the EPA MCL 4.0 mg/L and SMCL 2.0 mg/L.

Fluoride is

typically added in small quantities to public water supplies the optimum

concentrations for public systems 0.8 - 1.2 mg/L. Excessive levels of fluoride

can cause fluorosis or bone cancer over long term exposure.

Treatment for

excessive levels of fluoride in water is typically reverse osmosis which will

remove all fluoride and minerals from water.

The pH of water is a

measure of the acidity or alkalinity.

The pH is a logarithmic scale from 0 – 14

with 1 being very acidic and 14 very alkaline.

Drinking water should be between

6.5 and 7.5.

For reference and to put this into perspective, coffee has a pH of

around 5 and salt water has a pH of around 9.

Corrosive water, sometimes also

called aggressive water is typically water with a low pH. (Alkaline water can

also be corrosive.)

Low pH water can

corrode metal plumbing fixtures causing lead and copper to leach into the water

and causing pitting and leaks in the plumbing system.

The presence of lead

or copper in water is most commonly leaching from the plumbing system rather

than the groundwater.

Acidic water is easily treated using an acid neutralizing

filter.

Typically these

neutralizing filters use a granular marble, calcium carbonate or lime.

If the

water is very acidic a mixing tank using soda ash, sodium carbonate or sodium

hydroxide can be used.

The acid

neutralizing filters will increase the hardness of the water because of the

addition of calcium carbonate. The sodium based systems will increase the salt

content in the water.

Water that contains

high levels of dissolved minerals is commonly referred to as hard.

Groundwater

very slowly wears away at the rocks and minerals picking up small amounts of

calcium and magnesium ions.

Water containing

approximately 125 mg/L can begin to have a noticeable impact and is considered

hard. Concentration above 180 mg/L are considered very hard.

As the mineral

level climbs, bath soap combines with the minerals and forms a pasty scum that

accumulates on bathtubs and sinks.

You either must use

more soap and detergent in washing or use specially formulated hard water soap

solutions.

Hard water can be just a minor annoyance with spotting and the

buildup of lime scale, but once water reaches the very hard level 180 mg/L or

10.5 grains per gallon, it can become problematic.

Hard water spots

appear on everything that is washed in and around the home from dishes and

silverware to the floor tiles and cars.

When heated calcium carbonate and

magnesium carbonate are removed from the water and form a scale (lime scale) in

cookware, hot water pipes, and water heaters.

Water softening systems are used to address the

problem are basically an ion exchange system.

The water softening system consists of a mineral tank and a brine tank.

The water supply

pipe is connected to the mineral tank so that water coming into the house must

pass through the tank before it can be used.

The mineral tank

holds small beads of resin that have a negative electrical charge.

The calcium and magnesium ions are

positively charged and are attracted to the negatively charged beads.

This attraction makes the minerals stick to the

beads as the hard water passes through the mineral tank.

Sodium is often used

to charge the resin beads.

As the water is softened, the sodium ions are

replaced and small quantities of sodium are released into the softened water,

thus the salty taste of softened water.

When the water softening system is recharged the

excess sodium solution carrying the calcium and magnesium is flushed to the

septic system which may shorten the life of the drain field.

At the present time

the EPA guidance level for sodium in drinking water is 20 mg/L.

This level was developed for those restricted to a total sodium intake of

500 mg/day and does not necessarily represent a necessary level for the rest of

the population.

Based on taste of

the water levels of sodium should be below 30 to 60 mg/L based on individual

taste. Water softening systems add sodium.

Reverse osmosis

systems and distillation systems remove sodium and are safe for household use,

but addressing hard water by using vinegar to descale pots and dishwashers,

regularly draining hot water heaters, and using detergents formulated for hard

water might be a better solution for you.

Arsenic

is not a common contaminant in groundwater that has not been impacted from

surface runoff.

Arsenic can be

caused by erosion of natural deposits, but is more typically caused by

runoff from orchards, runoff from glass & electronics production wastes, or

leaching from coal ash disposal of or agricultural chemical mixing areas.

The EPA standard for

arsenic is 0.01 mg/L. Arsenic removal depends on the type of arsenic (there are

two types) and the other contaminants present in water.

Arsenic removal

methods or systems include anion exchange, reverse osmosis, activated alumina,

and other types of adsorptive media filters.

Each method has its limitations,

advantages and disadvantages and should be chosen based on additional analysis.

Elizabeth Ward was awarded an MBA from the University of Pittsburgh and an MS ChE

from Polytechnic Institute of NYU, worked as a chemical engineer for both the

US EPA in DC, and at DuPont before working in finance and then becoming

consultant with Washington Advisors and is the author of "The Lenders

Guide to Developing an Environmental Risk Management Program." Elizabeth

retired from Washington Advisors and began her volunteer career and is

currently the Treasurer of the Prince William Soil and Water Conservation

District.

You might also like:

.

|

Multi-Media Filter, Highly-Activated Carbon Filter,

Zeolite-Process Water Softener With Brine Tank,

Fiberglass Ballast-Type Pressure Tank

(fully automatic backwash & regeneration)

|

PURICARE

Water

Treatment

Systems

.

.

...

Aganan, Pavia, Iloilo, Philippines

...

CLICK HERE . . . to view company profile . . .

No comments:

Post a Comment