..................................................................................................................................................................

Gypsum As Construction Material

|

| Gypsum Wall Panels and Ceilings Used for Office Interior |

Gypsum Products and Properties as a Building Material for

Construction

Neenu Arjun

Gypsum

is one of the widely used construction material mainly in interior designing.

Properties

and products of gypsum to be used as building material in construction works

are discussed.

Gypsum

is used as surface material. Its application is prominent in wall and ceiling

construction. The use of gypsum can also be done at the field in the form of

plaster.

It

is also manufactured as a prefabricated unit, like gypsum board which is bought

at the time of installation.

Production

of Gypsum for use in Construction Works

Gypsum

is a white to gray mineral found in the earth’s crust.

It

is chemically known as hydrous calcium sulfate (CaSO4.2H2O) which are obtained

through mining from vast veins. It’s in different forms. It is seen as sand in

certain areas.

The

gypsum stone, which is called alabaster has the property to be carved to any

sculpture forms. This stone is translucent in nature.

It

consists of around 30% of bounded water in natural state. Water is taken out

from it through continuous heating till its white powder form is obtained.

Process

of Gypsum Production

The production of gypsum can be mentioned in following stages:

Excavation

Crushing

Grinding

Calcination

Cooling

and Pulverizing

Packing

|

| Gypsum Production Layout |

They

are also seen deposited in the sea water or lake. Then it is crushed into

particles of size approximately 25mm and subjected to grinding.

The

next main stage in its production is heating of the ground material, it is also

called as calcination.

Here

its particles are heated to 100 to 190-degree Celsius which result in three

forth of water loss from the particle.

This

process is called as the incomplete calcination or low burning process. Which

can be represented by the chemical equation:

CaSO4.2H2O

= CaSO4.1/2 H2O + 3/2 H2O

CaSO4.1/2

H2O = Plaster of Paris

The

temperature is further increased above 190 degrees Celsius which forms high

burning process or complete calcination:

CaSO4.2H2O

= CaSO4 +2H2O

CaSO4

= Gypsum-Anhydrite

For

the manufacture of drywall and plaster material the mined gypsum is used as the

raw material.

Synthetic

gypsum is used in more amount for manufacture.

The

wet limestone which is a combination of calcium and water, when combined with

sulfate forming calcium sulfate or gypsum is called as a chemical gypsum or

synthetic gypsum.

Why

use Gypsum in Construction Works?

The

ability of gypsum to give a comfortable and aesthetic ambiance as a

construction material increase the demands of gypsum.

It

is nature’s product that is commonly available. It is free of odor.

Nowadays

many of the interior and the exterior construction features are mostly governed

by gypsum construction or gypsum products.

The

advancement of gypsum construction in a continuous process is due to its

reduced time and cost of construction.

With

time, gypsum products gain increasing properties like increased fire

resistance, acoustic properties for noise insulation, etc..

Properties

of Gypsum as a Building Material

The

properties that are inbuilt in gypsum that facilitates its huge demand in

construction are explained in this section.

The

main properties of gypsum products are:

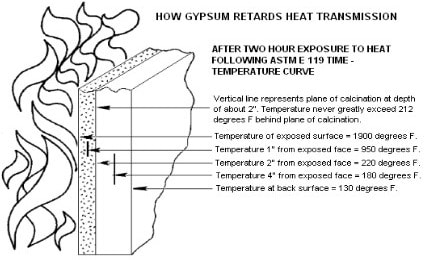

Fire

Resistance of Gypsum

|

Fire Resistance Behavior of Gypsum

|

Say

a gypsum plaster board of 15mm thickness would possess almost 3 liters of

crystal water within

it.

it.

When

fire approaches the water, it undergoes evaporation resulting in a protective

layer covering the gypsum product. This would help in stopping the spread of

fire to further materials.

Non-Combustible

Property of Gypsum

As

explained the heating up of gypsum products results in heating up of water

crystals present in the gypsum material.

This

dehydration of gypsum by heat is called as calcination.

The

calcination results in a covering over the materials that stop it to undergo

combustion and allow the material near them to maintain a lower safer

temperature.

Even

after complete calcination of water crystals, the residue would behave like an

insulating layer till it gets separated.

Gypsum

is considered as a good fire retarder because of its noncombustible property

and its capability to delay the spreading of fire for hours depending upon what

extend the gypsum products are used.

Acoustic

Properties of Gypsum

Gypsum

products are developed to focus more on sound insulation properties.

Other

methods like masonry would act good, which is commonly used in a higher

thickness that now is found less demanding compared to gypsum.

Gypsum

plasterboard is specially designed for noise reduction and prevent

reverberation. Incorporating an air space between two solid gypsum walls bring

higher acoustic performances, by restricting the noise to pass through.

For

example, instead of a masonry wall of 110mm thickness, we can install a drywall

of 75mm thickness to achieve same sound performance.

Thermal

Properties of Gypsum

The

thermal properties rendered by the gypsum construction would enable good

balancing of indoor humidity and temperature.

Gypsum

construction incorporating cavities, like plasterboard or formwork construction

with gypsum gives extra insulation properties.

Use

of plaster boards in interior construction acts as a vapor barrier preventing

indoor humidity.

Types

of Gypsum Products and their Uses

- Gypsum

Plaster Boards –Plasterboard are

panels used as partitions and for the lining of walls and the ceilings.

- Used

for Plaster for Decoration – The

combination of gypsum powder with water makes gypsum plaster that support

the formation of beautiful aesthetically pleasing linings for ceilings or

wall. They help in molding as well as shaping.

- Used

for walls and ceiling

- Gypsum

plaster Blocks used as partitions and as tiles

- Used

for self-leveling screeds

- Fiberboard

with Gypsum

Advantages

of Gypsum as a Building Material

A

set of outstanding advantages is shown by gypsum as a construction material.

Some of the main advantages are mentioned below:

· Delivers

Smooth Surface – It is used

as a plaster material if properly done would provide us with a smooth white

finish, which is free of cracks as well as scars. This is a highlighting

property when it comes to indoor finishing.

· Balance

Indoor Atmosphere – It is of

natural origin. They have a natural capability of balancing the indoor climate

as well as humidity.

· It

is environmental friendly

· It

is fire resistant in nature

· It

has high thermal and acoustic insulation

· It

provides good aesthetic and functional features – The creativity of architects is boosted by the

incorporation of gypsum products, within the budget. It provides a variety of

stunning design options.

· Ease of

Installation – Using

gypsum products, for example, for an internal wall construction, we just need

to fix the frame and fill up the joints. The full process is clean, easy and

fast. Using gypsum plaster as a final finish reduces the work of additional

painting. The white finish itself give a clean appearance.

· Variety

of Gypsum Products – A large variety of gypsum products is available that meets several

practical and aesthetic requirements. The choice of the right product is made

with the help of unique packages that is given by the manufacturers with

adequate technical assistance.

Neenu Arjun is a Civil and Structural Engineer and has experience

in Design of Concrete and Steel Structures. She is an Author, Editor and

Partner at theconstructor.org.

I read that Post and got it fine and informative. Commercial Kitchen

ReplyDeleteI have bookmarked your blog, the articles are way better than other similar blogs.. thanks for a great blog! https://westasianetwork.com/ashford-formula-dubai.php

ReplyDelete