........................................................

Tubes vs. Pipes

What are the main differences?

What are the main differences?

Francesco

Grillo

Understand the 12 significant differences between steel tube and

steel pipe in detail from the industry experts. Resolve the tube vs. pipe

confusion.

Ever wondered what to call a cylindrical

section? A pipe or is it a tube?

Confusing, isn’t it?

Both the tools appear to be working on the same hollow cylindrical

concept. Regardless of how similar they appear, tube and pipe have dramatically

different characteristics.

What exactly is the actual difference between pipe and tube?

Let’s hunt pipe vs tube down!

The difference is in the details!

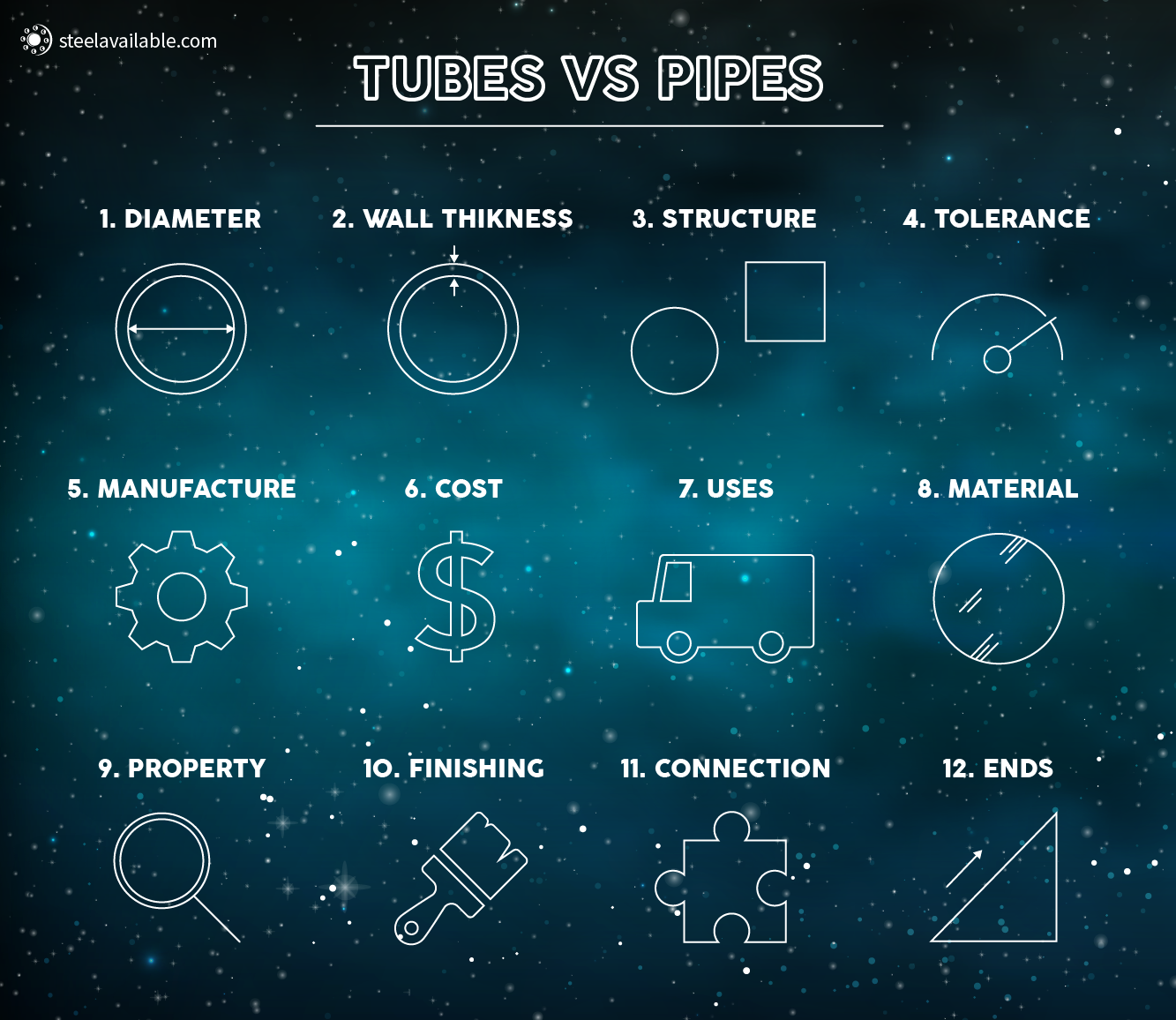

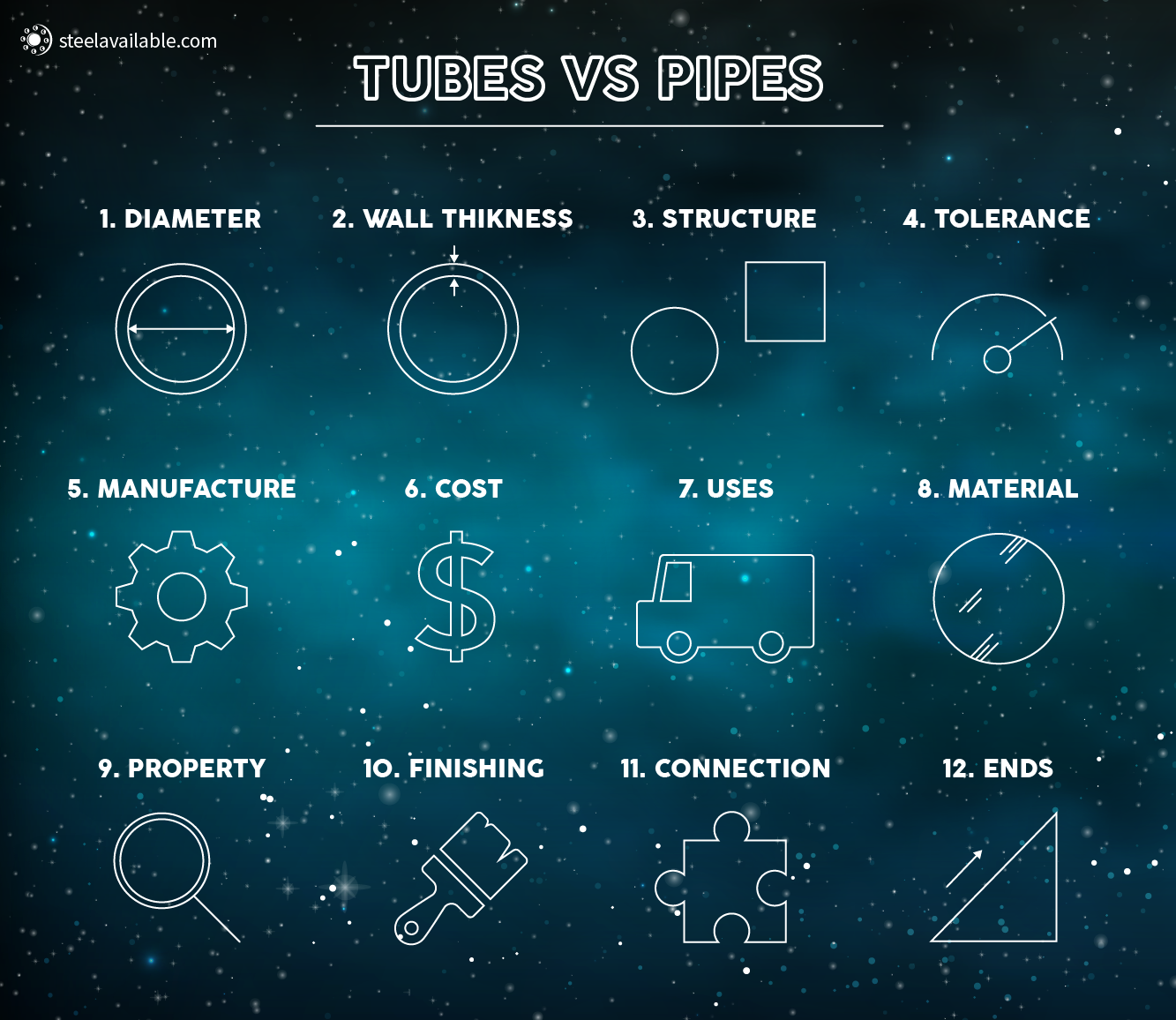

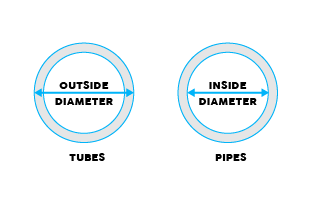

1. DIAMETER

While determining the actual size, tubes and pipes are

measured differently.

A tube is measured with the help of exact

outside diameter (OD) with a set range of wall thickness. The

wall thickness is vital as the tube’s strength is dependent on it.

On the other hand, we measure a pipe by using a nominal

outside diameter. The most important property is the capacity or the inside

dimension (ID).

Pipes accommodate larger applications with sizes that

range from a half-inch to several feet. Tubes are generally used in

applications that require smaller diameters. While

a 10-inch pipe is common, it is rare that you will find a 10-inch tube.

2. WALL THICKNESS

The wall thickness is an important factor while

differentiating between pipes and tubes.

The thickness of a tubing is often specified by a gauge

for thinner thickness and for thicker tubing it is

indicated by fractions of an inch or millimeter. The normal

range of tubing is 20 gauge, which is 0.035 inch up to a thickness of 2 inches.

The wall thickness of a pipe is referred to as a

pipe schedule thickness. The most common pipe schedules

are:

• SCH20,

• SCH40,

• and

SCH80.

SCH40 is the most common and SCH80 is quite heavy.

3. STRUCTURE

A tube’s structure does not have to be round always. It can be square or rectangular too. They are

usually seam welded.

Pipe, on the

other hand, is always round and rigid. It cannot be

shaped easily without the use of a special equipment. Pipes are usually

seamless and pressure rated to avoid leakages as they usually carry liquids or

gases.

4. TOLERANCE

Comparing the tolerance of both tubes and pipes, the

tolerance for pipes is looser than tubes. Pipes are usually used for

transporting or distributing, therefore the properties of pressure,

straightness, or roundness are strictly specified.

5. MANUFACTURING PROCESS

The materials and the manufacturing techniques of both

pipes and tubes differ.

Tubes require a higher level of processes, tests, inspection. As a result,

the delivery period is longer too. The yield of tubes is comparatively much

lower than the pipes.

Instead, the manufacturing process of a pipe is easier in

comparison to tubes and more often undergoes mass production.

6. COST

The manufacturing of tubes utilizes much more labor,

energy, and material. Therefore, in case of same material, the production

cost of tubes is usually higher than pipes.

The manufacturing process of pipes is easier and they are

always manufactured in large lots. This lead to a cutting in the cost of

pipes.

7. USES

Pipes are used mainly for transportation of fluids and

gases like water, oil, gas, propane

etc. Therefore, the outside and inside diameter is the key measurement and

pressure rating is important.

At the opposite, the main use for tubes

is for structural purposes such as scaffolding. They are

often put to use in applications that call for precise outside diameters.

Therefore, the outside diameter is vital as it indicates how much the tube can

hold.

8. MATERIAL

Pipes are usually made of carbon steel or low alloy steel.

Tubes instead are made of mild steel, aluminum, brass,

copper, chrome, stainless steel, etc.

The difference in materials is also a reason for the

difference in the cost and applications.

Some widely used steel pipe standards or piping classes

are:

• The

API range – now ISO 3183. E.g.: API 5L Grade B – now ISO L245 where the number

indicates yield strength in MPa

• ASME

SA106 Grade B (Seamless carbon steel pipe for high temperature service)

• ASTM

A312 (Seamless and welded austenitic stainless steel pipe)

• ASTM

A36 (Carbon steel pipe for structural or low pressure use)

• ASTM

A795 (Steel pipe specifically for fire sprinkler systems)

9. MECHANICAL AND CHEMICAL

PROPERTIES

The pressure rating, yield strength, ductility properties

are more important for pipes. However, for tubes, the hardness, tensile

strength, and high precision is the key to high quality.

Carbon, Manganese, Sulphur, Phosphorus, and Silicon are

the main chemical elements for pipes. While for tubing, the microelements are

very important to the quality and process.

10. SURFACE FINISHING

Pipes need to be painted or coated to anti corrosion or

oxidation for outdoor field transporting or underground transporting.

Tubes often go through sour cleaning or special polish

treatment for their particular field uses.

11. CONNECTION

Connecting one pipe to another is much more of a labor intensive

process as it requires welding,

threading, or flanges along with its relevant equipment.

On the contrary, tubes can be joined quickly and

effortlessly with flaring, brazing, or coupling. Tube assemblies can also take

place through tube fittings where high standards of construction are

needed.

Pipe welding is safer that tube joining.

12. THE ENDS

Pipe ends are usually in a plain or beveled form. Whereas, tubes generally come with coupling ends

or special end finishes like irregular ends, special screw thread etc.

Any further doubts on this topic? If

you want to have more information or you want to share your opinion, contact us

at info@steelavailable.com.

We are Steel

Available, an online supplier relationship management

and sourcing platform. We aim to connect suppliers and buyers from the heavy

industry. We are developing the first ecosystem in the heavy industry which

will allow clients to efficiently manage and automate their supply chains using

web-based tools and services. Our goal is to reduce the hidden risk in value

chains. We do it by providing the information that matters, from compliance to

quality assurance, creating value for all stakeholders.

To get more information, please download our brochure.

Written by:

Francesco Grillo

Co-founder & CEO @SteelAvailable

No comments:

Post a Comment