..............................................................................................................................................................

Author: Sara Peters

Check

valves are simple valves.

They

use forward flow to open the valve, then automatically close when flow stops,

preventing reverse flow from making its way back through the valve.

They

don’t require power to function, and they don’t require a whole lot of

attention or maintenance.

They

do get a lot of attention, however, when they slam.

What

causes the slam?

A

check valve relies on gravity and/or reverse flow to close completely.

Opportunity

for check valves to slam frequently occurs at pump shutdown.

When

a pump stops, gravity and reverse flow slam the check valve shut.

Because

fluid is non-compressible, it creates a pressure or shock wave (water hammer).

The

fluid continues to flow back and forth until friction losses cause the wave to

settle.

Slamming

check valves cause serious pressure surges in a system that rattle pipes and

damage equipment.

Some

people assume that’s just what check valves do. "No matter what, they’re

going to slam."

But

that’s just not the case. Usually, the real cause of these problems, stems from

poor sizing and selection, not the type of valve itself.

Minimizing

Slam Through Proper Sizing

Oftentimes

check valves are selected based on the pipe size and the desire for the largest

Cv possible.

(CV

stands for “coefficient of flow” for valves and demonstrates a valve’s capacity

for liquid to flow through it.)

Of

course, you want the ability to put as much fluid through the valve as

possible, right?

Makes

sense, except this completely disregards the fact that flow conditions

determine the internal performance of a check valve because the disc is

directly in the flow path.

If

there is not enough flow to keep the valve fully open with the disc reaching

the ceiling of the check valve, the disc will move up and down, resulting in

pre-mature wear, potential for failure, and a higher pressure drop.

For proper check valve selection, consider the following:

· Line sizing

· Application data

(fluid characteristics, including temperature and pressure)

· Seat type

· Installation

(horizontal or vertical)

· End connection

· Valve rating

· Material

compatibility with the medium

· Envelope dimensions

· Leakage

requirements

Selecting

a valve of the proper size will have an impact on the amount of water hammer

felt by the piping system.

Selecting

the right type of check valve

Another

solution to slamming check valves is to look at the type of check valve used in

the application.

Silent,

ball, and resilient hinge are alternatives to the traditional swing check

valve.

They

each carry different characteristics with varying degrees of pressure drop and

closure speed.

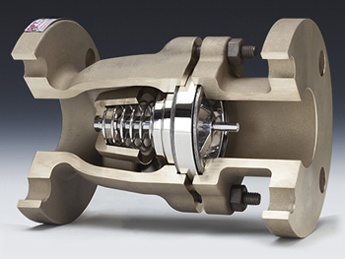

Silent

Check Valves

Silent

or spring–assisted check valves do not rely on gravity or reverse flow to

close.

Instead,

the spring closes in about one-tenth of a second, the valve before reverse flow

has an opportunity to slam the valve shut.

It

is able to close quickly because it has a shorter distance to travel than the

flap on a traditional check valve.

This

video from DFT illustrates how pressure spikes in the system are greatly

reduced with a silent check valve.

Ball

Check Valves

Ball

check valves are economical and very simple valves.

They

sometimes utilize a rubber coated ball that floats up and out of the way while

flow passes through the valve, and seats when flow stops.

This

particular valve closes slowly, so the potential for slamming is high.

There

are other styles of ball check valves that work similarly to silent or in-line

check valves. These are called cone check valves.

Resilient

Hinge Check Valves

Resilient

hinge check valves are very similar to the traditional swing check valve.

The

major difference is that a rubber molded disc flexes up and out of the way when

fluid flows through the valve. The flap does not rotate around a hinge pin.

It

has a shorter stroke than a traditional swing check valve, reducing the closing

time of the valve and minimizing the potential for water hammer to occur.

Conclusion

Each

of these valves have different characteristics, features and benefits that

should be carefully selected for just the right fit into a system.

If

you’re experiencing issues with a check valve or need to select a new one for

your process, talk to an engineer experienced in selection/sizing of these

valves.

Doing

so will help your system perform at its highest efficiency while reducing slam

and requiring less maintenance.

Sara Peters leads Crane Engineering's blogging team, coming up

with fresh stories and insights for our readers to apply to their every day

work.

No comments:

Post a Comment