................................................................................................................................................

................................................................................................................................................

Cloud Seeding

How Does Cloud Seeding Work?

Rinkesh

The weather has

been, for Millenia, a natural phenomenon that could not be altered by human

activity.

For instance, no

one could manipulate the atmosphere so that it rains. However, in the last

several years, human intelligence and technology have changed that.

Humans can now

control the weather, including ‘making it rain’ literally – through a process

called cloud seeding.

It basically is the

enhancement of natural precipitation.

The process makes

water vapor into clouds, turning into precipitation and into rain that would

otherwise not fall on earth.

It is the most

widely used technique in the modification of weather.

What is Cloud Seeding?

Cloud seeding, rainmaking,

or man-made precipitation enhancement is a way to artificially modify the

weather by spreading clouds with small particles, to make it snow or rain.

In other words,

cloud seeding is all about manipulating the clouds so that it rains. Clouds

consist of water droplets or ice crystals.

They form when

water vapor in the atmosphere cools and later condenses around a particle of

dust or salt.

These dust or ice

particles, also known as condensation nuclei, facilitate the formation of

raindrops or snowflakes.

Without the

condensation nuclei, rainfall cannot form and, therefore, precipitation does

not occur.

Cloud seeding

artificially adds condensation nuclei to the atmosphere, significantly

improving the ability of a cloud to produce rain or snow.

With the added condensation

nuclei, cloud seeding provides a base for snowflakes or raindrops to form.

It, therefore,

follows that after cloud seeding, precipitation in the form of rain or snow

will fall from the clouds back to earth.

The intent or goal

of cloud seeding is to increase the rain or snow precipitation, suppress hail,

reduce lightning, or even dissipate the fog.

It is an efficient

tool, especially in arid areas of the world, where rainfall is minimal under

ordinary circumstances.

Cloud seeding has

been practiced by a number of countries including India, the United Arab

Emirates, the United States, China, and the United Kingdom.

China has used the

technology dependently in dry areas of the country.

The UAE has used

the technology since the 1990s, including in 2015 when they pumped about $5

million into their Research Program for Rain Enhancement Science.

The US has employed

the technology since the 1950s, especially in the Rocky Mountains,

Sierra Nevada, and other mountainous and dry areas.

During the 2008

Beijing Summer Olympics and during the wedding of the Duke and Duchess of

Cambridge, the technology was used to prevent rain.

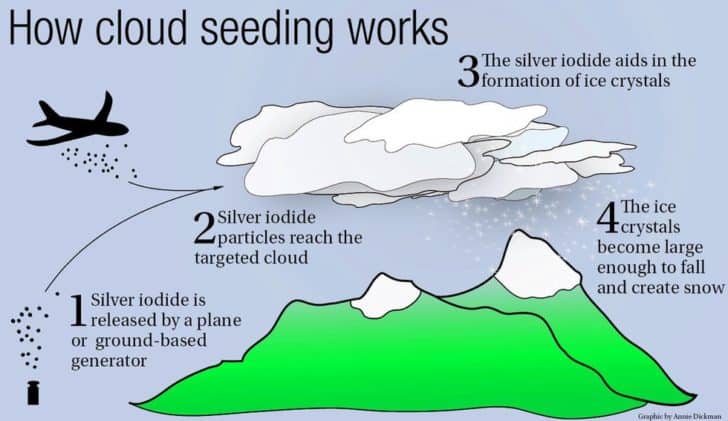

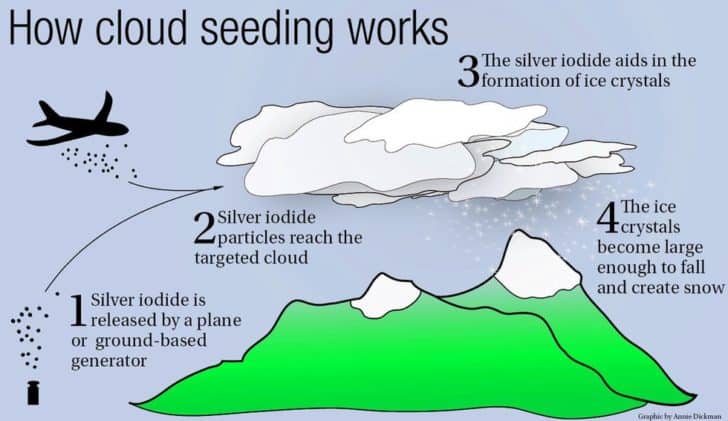

How Does Cloud Seeding Work?

The enhancement of

rainmaking or precipitation was first done in 1946 when Vincent Schaefer and

Bernard Vonnegu, American scientists at General Electric, were successful in

seeding a cloud with dry ice.

They climbed onto a

small plane and seeded a cloud with dry ice floating above Schenectady, New

York. They then watched as the snow fell from the base of the ice.

After that

experiment, Schaefer became referred to as the ‘Snow Man’. According to Guo

(2018), three methods can make cloud seeding work:

1.

Spraying water into warm clouds

2.

Dropping ice into cold clouds

3.

Spraying silver iodide or similar crystals into a cold cloud,

either from the ground or over the cloud from an airplane

Regardless, the

types of clouds play a vital role in ensuring the process is successful.

Large droplets are

required if rain is expected to form, meaning maritime clouds are a better

source of rain than continental clouds.

The temperature of

the cloud is also important.

For instance,

cumulus and stratiform clouds, whose temperature is below -7°C, would be

accompanied by precipitation within 25 minutes.

Types of Cloud Seeding

1. Static Cloud seeding

This first of three

methods work when a chemical compound is spread onto the clouds.

It is the most

commonly used method and involves the spraying of particles of salt, like

silver iodide and chloride onto clouds.

Silver iodide (AgI)

exists in the environment naturally and is not harmful to humans or wildlife.

To do so, a special

aircraft, rocket, or other dispersion device is used.

The salt particles

act as a condensation nucleus, drawing water vapor within the cloud towards

them.

Moisture will then

latch onto them, condensing into water droplets. Subsequently, raindrops form,

leading to rainfall.

2. Dynamic Cloud Seeding

This second type of

seeding works by boosting the vertical air currents, encouraging more water to

pass through the clouds.

It, therefore,

translates to more rain.

For it to work,

about 100 times more ice crystals are required as compared to the static cloud

seeding method.

It is a more

complex method as it relies on a sequence of events working properly.

Scientists within

the atmospheric science departments as well as other researchers have broken

the dynamic cloud seeding method

into eleven separate stages.

If one of the

stages fails or its outcome is unexpected, the entire process is ruined.

It also makes the

technique less dependent as compared to the static cloud seeding method.

3. Hygroscopic Cloud Seeding

This last type

utilizes the dispersal of salts through flares or explosives onto the lower

parts of a cloud.

The salt will

become bigger and water will join it.

It is a relatively

new method that has been described as ‘promising.’ It, however, requires more

research.

Negative Effects of Cloud Seeding

1. The process is not 100% effective

Despite the process

being touted as highly successful in creating rain, it has raised concerns as

to its actual effectiveness.

The main question

that arises is, would rain have come in a certain place even without the need

for the seeding?

Cloud seeding

becomes irrelevant if it would have rained regardless of it being used.

It becomes

difficult to ascertain if fluctuations in the level of rainfall, occurring

during cloud seeding times, are produced by seeding or could have occurred

naturally.

2. The process is very expensive

It is an innovative way of

creating rainfall, especially in arid areas. However, it is an expensive

process.

In China, for

instance, the country uses between $60 and $90 million every year on such

weather modification projects.

Between 1995 and

2003, the country used $266 million for the same causes.

As already

mentioned, the UAE spent about $5 million in 2015 for its Research Program for

Rain Enhancement Science.

Such monies could

be used to fund other projects, given that it will inevitably rain.

Also, if the aim is

to bring rain to areas severely affected by climate change,

wouldn’t it be easier to tackle global warming and climate change, as it would

bring a long-lasting solution?

3. The truth about silver iodide is that it may potentially

contain dangerous substances

Despite silver

iodide being termed as safe for the environment, there remain concerns about

exposure to the same, especially with regards to soil contamination.

Silver iodide has

been known to result in incapacitation and possible residual injuries to humans and other animals,

especially after chronic exposure.

The toxicity of

silver and its compounds in the environment might be low, but they are negative

effects nonetheless.

4. Cloud seeding is not the end solution; it may actually

worsen global warming and climate change

It has been argued

that cloud seeding is just a way of sweeping the effects of pollution and

climate change under the rug.

Using cloud seeding

to bring rainfall does not negate the fact that climate change exists

and the process does nothing to fix the initial problem, which is global

warming and climate change.

Since the process

is expensive, it would be easier to fix the bigger problem and enjoy the

long-term benefits of a better climate.

5. The results might be damaging – more or less rain!

The end results of

cloud seeding are either having no rain, like during the 2008 Beijing Olympics

or having more rain, especially in dry areas.

However, sometimes,

the results have been damaging.

In 1974, a

hurricane on the US East Coast was seeded using dry ice.

The hurricane did

not hit the area but moved to the west in Georgia. It caused severe damage,

leading to General Electric Corporation being sued.

Operation Cumulus

was as well an alleged to be series of secret scientific experiments being

conducted in the UK between August 4th and 15th What followed were flash floods in Devon

village in Lynmouth, England, killing 35 people.

6. Cloud seeding can be used for destructive purposes

According to Brown

(2018), only 56 countries practiced cloud seeding activities in 2016.

This means the

possibility of more powerful countries using the process to attack other

countries.

For instance, the

US used cloud seeding to cause a monsoon in Ho Chi Minh, Vietnam, during the

Vietnam War, as a tactic against the Vietnamese soldiers.

Rinkesh. A true environmentalist by heart ❤️. Founded Conserve

Energy Future with the sole motto of providing helpful information related to

our rapidly depleting environment. Unless you strongly believe in Elon Musk‘s

idea of making Mars as another habitable planet, do remember that there really

is no 'Planet B' in this whole universe.